Separators

Everything You Need to Know About Separators

Separators are essential to oil and gas production, as many refinery workers rely on their efficiency to make extracting oil much more manageable. But what are these devices, and why are they essential to the oil and gas business?

Learn about the different types of separators, why they are so important, and how they work.

Make sure you read this page in full so you can learn everything you need to know about separators. Anyone looking to buy or work in the field will need a general understanding of these magnificent gadgets.

Showing all 10 results

-

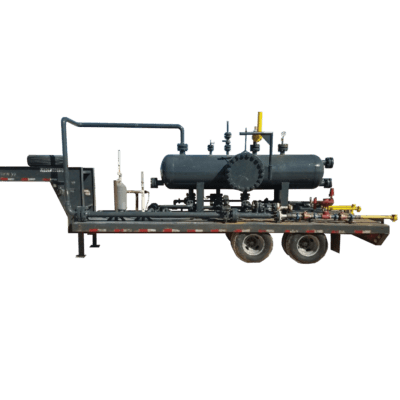

108″ X 36′ 100 PSI Horizontal Separator

-

30″ x 10′ 1440 PSI Horizontal Separator (3-Phase)

-

30″ X 10′ 2000 PSI Horizontal Separator (3-Phase)

-

36″ X 10′ 1440 PSI Horizontal Separator (3-Phase)

-

36″ X 15′ 1440 PSI Horizontal Separator (3-Phase)

-

60″ X 12′ 500 PSI Horizontal Separator

-

60″ X 15′ 675 PSI Horizontal Separator (4-Phase)

-

60″ X 20′ 675 PSI Horizontal Separator (4-Phase)

-

72″ X 15′ 260 PSI Horizontal Separator

-

72″ X 15′ 500 PSI Horizontal Separator

What Is a Well Test Separator?

Simply put, a separator is a device that divides a substance into its base elements or constituents. In the context of oil and gas, they split the liquid, water, gas, and solid components of materials retrieved from the ground.

The original separator came about around 1890, and its primary use was to divide the milk fat from dairy products. Nowadays, large-scale separators are used in numerous shoreline oil industries to produce gas and liquid petroleum.

Phase separation is a process that relies on intricate machinery to get it done both quickly and economically. Efficient harvesting of oil and gas has become more critical than ever, giving rise to the need for specialized individuals to handle these operations.

Companies will need to know how to deal with liquid contaminants and have basic knowledge of gravity and momentum. Due to the increasingly high standards of gas transmission lines, producing dirty constituents is no longer tolerated.

There are numerous separators worldwide, and organizations classify them by their positioning or the number of fluids they separate. People use them in

● Gas facilities

● Upstream compressors

● The liquid traps found in transmission lines

● Dehydration intakes

● Gas Sweeteners

Their versatile use has made them a staple in the global economy, giving them a solid place in today’s gas and oil market. In fact, due to the rising demand for natural gas, experts say separators will register a 3% compound annual growth rate by 2023.

What Are the different types of Separators?

As mentioned, separators receive classification through their orientation or the amount of liquid they are trying to separate. That means they receive names that reflect those categories, such as

● Horizontal

● Vertical

● Spherical

● Three-Phase

● Two-Phase

● Well Test Separators

● Four Phase Production Separators

Horizontal Separators

Horizontal separators forgo the use of gravity and gas pressure as a means of separating the agents. This physical advantage makes them highly versatile and allows industries to use them on many sites.

Their shape resembles their vertical counterparts, but they also have a collection system, surge drum, and tray packs. They can be found in several diameters and have a height range of 16ft to 120 ft.

Vertical Separators

Vertical Raiders are used to handle gas and liquid. Offshore platforms favor these vertical contractors because of their ease of use due to gravity. They are useful for onshore sites if gravity is not enough.

These centrifuges utilize a two-phase pressure system across the internal design, which allows them to distribute liquids across the top and bottom of their surfaces. They equip themselves with a collection system that gathers free liquids in a drum during a surge event.

The only drawback to these contractors is the sheer amount of space they need for operation.

However, studies say that the incredible utility and ease of gravitational separators, like the vertical iterations, can more than make up for any spacial downfall.

Spherical Separators

These devices are known for their compact design and their inexpensive price tag. On top of that, they are relatively simple to use, making separating constituents all that easier.

Unfortunately, they are not very efficient at their job because of their low gas-to-oil ratio during production. For this reason, you will not see many big-time refineries use this option in place of the bigger horizontal and vertical choices.

But, they have a place in several small-time operations requiring uncontaminated elements in a pinch.

Two-Phase Separators

Two-phase separators are known by numerous names, including “double effect vessels” and “two-stage separators.” They operate by placing two distinct dividers next to each other, where one is used to separate liquids used for stripping in the second stage.

Three-Phase Separators

A 3-phase separator is one of the more complicated types of separators because of uses a quick succession vertical stripping maneuver to retrieve gas constituents from a mixture of vapors, liquids, and solids.

Two chambers are arranged side-by-side in a vertical orientation, separated by a small space in which lies radial vanes. High-pressure liquids are sent through the veins to separate the oil from the gas. Gas escapes through vents overtop while the liquid comes to rest in a chamber below.

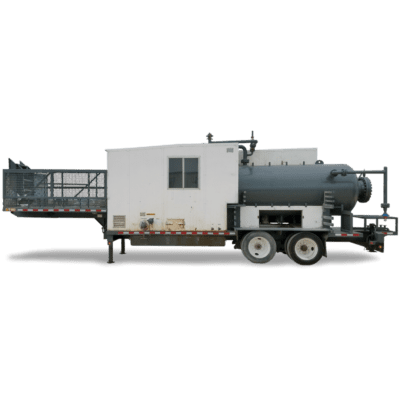

Well-Test Separators

A well-test separator is a chamber that collects small amounts of oils in gas to determine a measurement. They are essential for diagnosing problems, evaluating performance, and managing reserves.

They have other monikers such as “well testers” and “well checkers.”

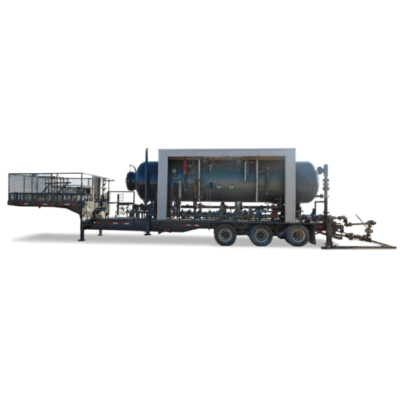

Four-Phase Production Separators

A four-phase production separator is a complex machine that separates gas, oil, water, and solids. Some of these separators feature tools that provide accurate measurements of the rates, providing users with helpful feedback from a reserve.

They come equipped with the standard features you would expect from a separator, including weir plates, mist extractors, and inlet deflectors. Since they are the most complicated piece of machinery for oil and gas refineries, they follow the most strict protocols regarding operation.

Get Your Separators From Tiger Safety

Separators come in many shapes and sizes and are essential for dividing more refined elements extracted from the Earth. They can be an excellent investment for many businesses that want to extract oil, gas, or other liquids.

Removing impurities from oil, gas, and water has been and will be a common practice for the foreseeable future, especially if certain global events muddy the waters for the natural gas economy, causing it to shoot up sharply.

Tiger Safety can provide you with high-quality equipment at an affordable price. With our extensive knowledge of the oil and gas industry, we won’t let you down. Get in touch with us today.