Well Testing & Production Equipment

In the oil and gas industry, there are many types of tests conducted on a regular basis to find important information. To find out what the maximum production of a well is, well testing is crucial!

Well testing allows you to determine a well’s productivity and flow capacity at certain flowing pressures and conditions. This process is not actually that simple. It requires a lot of effort and time. Plus, you need high-performance production equipment that makes this process possible.

Not sure what you’re looking for? See our Well Testing and Product Equipment information below or contact customer support if you need help.

-

Flow Iron (1)

-

Hydraulic Choke Manifolds & Control Units (2)

-

Choke Manifold (2)

-

Flare Trailers (2)

-

Monorail Trailer (2)

-

Plug Catcher (1)

-

Separators (10)

-

Sand Traps (8)

What is Well Testing?

Let’s start with the most basic question: what is well testing?

Oil and gas production requires constant improvement to provide the best benefits. However, you need the right and up-to-date information to apply these improvements. A well test is the execution of planned activities necessary to acquire important data.

The data acquired by a well test is analyzed to increase the understanding of the characteristics of the underground reservoir and properties of hydrocarbons therein. This test will also offer important information about the condition of a that well.

In short, the overall objective of well testing is to determine the capacity of the reservoir to produce hydrocarbons, such as condensate, natural gas, and oil. It provides data involving pressure and flow rate in the well, allowing you to make plans for the ongoing production phase.

Different Types of Well Testing

There are different sorts of well tests available. It’s worth mentioning that no two well tests are the same. They have unique purposes and require different equipment to perform the test.

To give you a better perspective, below, we have compiled a list of some of the most common types of well tests:

- Drill Stem Test – At the top of our list, we have the drill stem test. This test is a flow test performed in an open hole. The focus of the drill stem test is to obtain reservoir fluid samples, pressure buildup, short-term flow, and static pressure measurements to estimate damage extent and permeability.

- Drawdown Test – In the drawdown test, well pressure is measured while the rate is held constant. To conduct this test, you’ll have to shut-in the well until the pressure touches the static level. The most significant benefit of the drawdown test is that you can measure the reservoir size without losing any production.

- Buildup Test – The buildup test is considered one of the most used well testing techniques. In this test, the well is produced as normal until it attains a stabilized pressure. Afterward, it is shut in to record the pressure. This test might lead to loss of production: however, it gives the precise control of rate.

- Interference Test – Through interference test, you can attain large-scale property trends for a certain reservoir. As a result, you can get enhanced estimates of reservoir storativity and directional permeability.

- Banker’s Test – Banker’s test is a production and economical procedure that allows you to determine the sufficient rates that can be obtained from a certain well.

As you can see, there are several types of well tests that have different purposes. While some tests are carried out to determine the flow rate, others are necessary to demonstrate reservoir pressure in a certain well.

Furthermore, you cannot use a single instrument to conduct all these tests. You need proper and unique equipment designed for a certain test: discussed below!

Well Testing & Production Equipment – What You Need!

When it comes to well testing, you need the right tool for the right job. Unfortunately, selecting the best production equipment for well testing is not a piece of cake. This is because there are thousands of different designers and manufacturers out there that offer these productions, making it quite a pickle to pickle a single product.

You should invest some time before you invest your money. Do a little research and find the best production equipment for your well test.

To give you a better perspective, below, we’ve included a list of essential production equipment that you’ll require for well testing:

Flow Iron

Regardless of the type, you need flow iron for almost every well test. However, you have to make sure that you’re getting the perfect size for your well. You can get flow iron in these sizes:

- 1502 – 2”

- 1502 – 3”

- 206 – 3”

There are different types of flow irons available too. You can get thread flow iron, wing flow iron, and elbows flow iron from 1ft to 20ft.

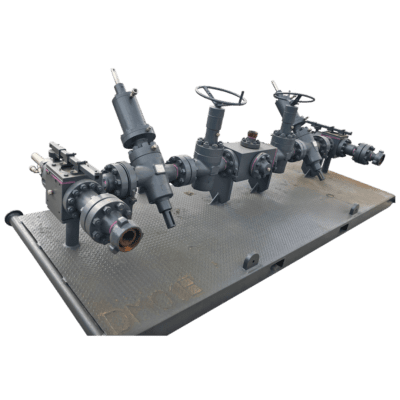

Choke Manifold

Another production equipment for well testing that deserves a spot on your list is the choke manifold. In well testing, a choke manifold is used to lower the reservoir’s pressure. This equipment consists of at least two chokes and high-pressure valves.

There are different types of choke manifolds available out there. While some have fixed chokes, others feature adjustable ones or a mix of both. This redundancy is required so that the flow can be directed through others if one choke has malfunctioned.

Normally, you can find two types of choke manifolds out there:

- 5-valve choke manifold

- 9-valve choke manifold

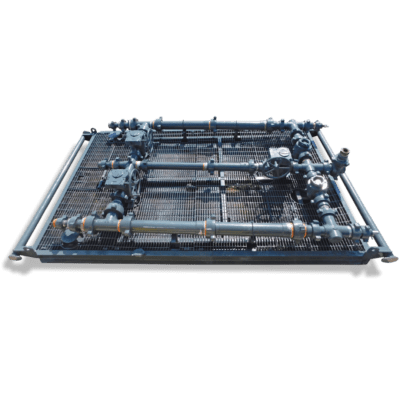

Hydraulic Choke Manifold & Control Unit

A hydraulic choke manifold has the same function as the normal choke manifold. However, it regulates the fluid flow between actuators and pumps in a hydraulic control unit. This one is more modern and versatile as it allows the controller to control how much fluid flows between the components.

This product will contain:

- 10,000 PSI Hydraulic Choke Manifold

- Hydraulic Command Center

Flare Trailer

Flares are safety devices used in petrochemical and refineries facilities. These devices are also used in well testing to burn excess hydrocarbon gases which cannot be recycled or recovered. You can get two types of flare trailers for your well tests, such as:

- 12” x 30’ Flare Trailer

- 60’ x 6” Flare Trailer

The 2nd one will provide more features and storage space. So, make sure to select a flare trailer that suits your testing procedure perfectly.

Monorail Trailer

For well testing, you also need a high-performance and durable monorail trailer to carry heavy tools and equipment from one place to another.

Plug Catcher

In well testing, plug catchers are also a must-have. These gadgets support easy cleanup by filtering fragments of loose rock, cement, and casing from the well and isolation plug remnants. Usually, there are two types of plug catchers available out there:

- Catcher with Single Barrel with Bypass

- Catcher with Dual Barrels

We suggest investing your money into a plug catcher that features dual barrels because they offer continuous filtration during blowdown activities. Furthermore, try to get a plug catcher made of corrosion-free material to ensure durability and a long lifespan.

Separator

Another production equipment necessary for well testing is the separator. A separator is used in exploration wells where emission phases might not be known. In that scenario, a separate will treat a wide variety of discharges, such as foaming oil, heavy oil, light oil, gas, and gas condensate, as well as solid particles and mud.

Separators are necessary for well testing because they help you minimize environmental risk, reduce cleanup time, and improve safety while getting the data you need. There are different types of separators available in the market. However, we suggest investing in horizontal separators.

Some of the most popular separators for well testing include:

- 108” x 36’ 100 PSI Horizontal Separator

- 30” x 10’ 1440 PSI Horizontal Separator (3-Phase)

- 30” x 10’ 2000 PSI Horizontal Separator (3-Phase)

- 36” x 10’ 1440 PSI Horizontal Separator (3-Phase)

- 36” x 15’ 1440 PSI Horizontal Separator (3-Phase)

- 60” x 12’ 500 PSI Horizontal Separator

- 60” x 15’ 675 PSI Horizontal Separator (4-Phase)

- 60” x 20’ 675 PSI Horizontal Separator (4-Phase)

- 72” x 15’ 260 PSI Horizontal Separator

- 72” x 15’ 500 PSI Horizontal Separator

Sand Trap

A sand trap is a small pit that is used as a setting pit to separate coarser solids that bypass the shakers. While well testing, you input the mud from one side of the setting pit that exits via an overflow at the other. Usually, a sand trap is discarded periodically to confiscate the settled contents, or the solids can be treated with a centrifuge or over a fine screen.

Conclusion

Well testing is crucial from time to time. Through this procedure, you can gather important information about a well and its reservoir. However, for well testing, you need the right production equipment.

To enjoy a smooth operation, you need a flow iron, choke manifold, hydraulic choke manifold, flare trailer, monorail trailer, plug catcher, separator, and sand trap. Keep in mind that all this equipment has something unique to offer. Therefore, you need to do your research before selecting the right product.

Additionally, well-testing production equipment is available in different sizes and prices. We suggest investing your money in a high-quality and expensive product that will last for decades!