The oil and gas industry is characterized by complex and potentially hazardous operations, necessitating the deployment of specialized equipment and systems to ensure safety and efficiency. One essential tool in this context is the choke manifold system, which plays an indispensable role in the control and management of well pressure fluctuations for both onshore and offshore oil and gas operations.

This article will delve into the importance of choke manifold systems, their functionalities, and how Tiger Safety Rentals can help you safeguard your operations by offering tailored equipment and support services designed to meet the industry’s most stringent safety requirements.

Choke manifold systems serve as key components in pressure management for drilling and production operations. They function by redirecting high-pressure fluids and gases away from the wellbore, allowing for the safe and controlled release of pressure. This process not only helps maintain optimal well pressure and prevent formation damage but also can serve to avert hazardous situations, such as kicks, blowouts, or equipment failures.

At Tiger Safety Rentals, we understand the significance of employing reliable, high-quality safety equipment and systems in the oil and gas field. As such, we provide choke manifold systems designed and built to meet the highest industry standards, ensuring that your operations remain safe, compliant, and efficient.

With our extensive experience and unmatched reach, you can trust that we are well-equipped to support your projects with the most advanced and cost-effective solutions available.

Understanding Choke Manifold Systems in the Oil and Gas Industry

Choke manifolds are vital components in the drilling process, as they help manage and control pressure fluctuations within the wellbore. These systems are engineered to handle varying pressure levels and fluid compositions, ensuring safe and consistent operations. Let’s delve deeper into the functionality and uses of choke manifolds in oil and gas extraction projects.

- Pressure Regulation: Choke manifold systems help regulate and maintain well pressure at safe levels throughout the drilling and production processes. Controlling the pressure within the well significantly reduces the risk of equipment failure, kicks, or blowouts, enhancing overall safety and productivity.

- Circulation and Flow Control: Choke manifolds not only manage wellbore pressure but also ensure proper fluid circulation. By accurately controlling the flow of drilling fluids, operators can maintain an optimal balance between fluid removal and pressure control, preventing damage to the formation and expensive downtime.

- Emergency Response: In the event of a sudden pressure surge or kick, choke manifolds act as a critical first line of defense in averting potential disasters. The swift redirection of high-pressure fluids and gases away from the wellbore allows for a timely and controlled release of pressure, effectively preventing catastrophic incidents.

Components of Choke Manifold Systems

Choke manifold systems consist of various individual components that work in harmony to handle pressure fluctuations in oil and gas operations. Some key components of these systems include:

- Choke Valves: Choke valves are adjustable instruments used to regulate the flow of fluids and gases. They play a crucial role in managing pressure fluctuations by accurately controlling the flow rate through the system.

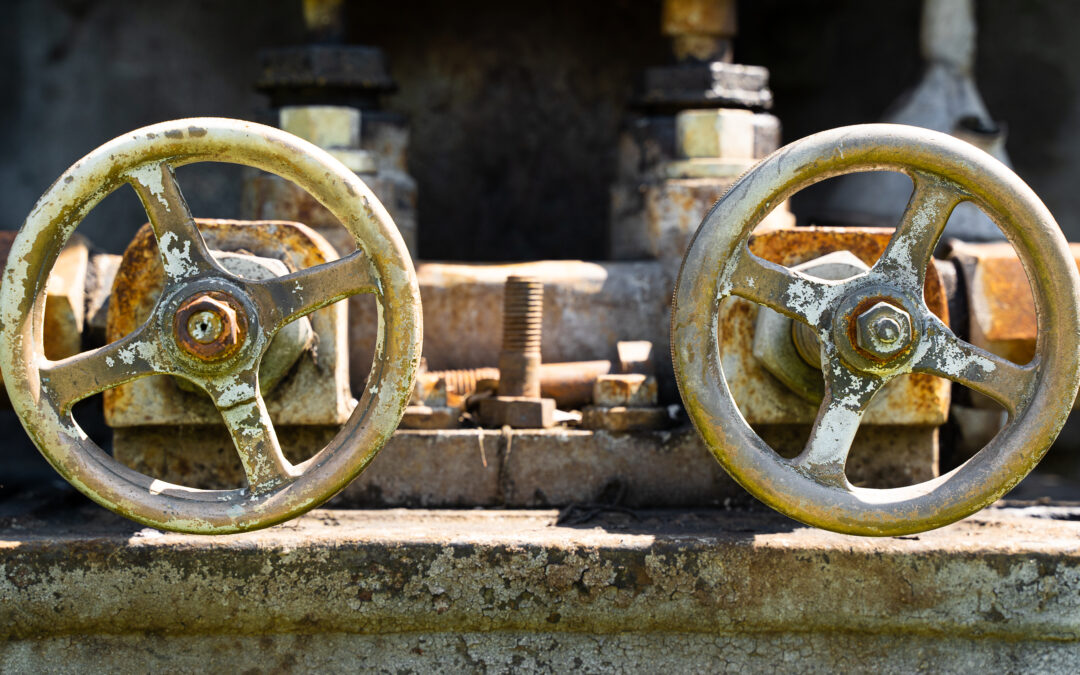

- Gate Valves: Gate valves are essential for isolating specific sections of the choke manifold system for maintenance or emergency response. They provide tight shut-off capabilities, ensuring that potential pressure surges do not compromise the integrity of adjacent components.

- Crosses and Tees: These components serve as connecting points within choke manifold systems, facilitating the redirection of fluids and gases to various pathways, allowing for optimal pressure control and fluid management.

- Piping and Connectors: Choke manifold systems require robust piping and connectors to handle the high-pressure fluids and gases. These components are designed to withstand extreme conditions and provide reliable, long-lasting performance.

Partnering with Tiger Safety Rentals for Choke Manifold Solutions

Choosing Tiger Safety Rentals as your partner for choke manifold systems offers numerous advantages for your oil and gas operations:

- Customized Solutions: We understand that each oil and gas project has unique requirements. At Tiger Safety Rentals, we are committed to providing choke manifold solutions tailored specifically to your needs, ensuring optimal performance and safety.

- Quality and Reliability: Our choke manifold systems are engineered to meet the highest standards, delivering reliable and robust performance even under the most demanding conditions.

- Expertise and Support: The Tiger Safety Rentals team offers unparalleled industry experience and technical expertise, helping you select the right choke manifold solution for your project. Our support extends from initial consultation to ongoing assistance throughout your operations.

- Flexible Rental Options: Through our rental services, you can access top-of-the-line choke manifold systems without the substantial upfront costs of purchasing equipment. Our flexible rental options enable you to optimize your operations while adhering to your budget.

Safety Considerations and Best Practices

When implementing choke manifold systems in your oil and gas operations, it is essential to follow safety guidelines and best practices to ensure optimal performance and worker safety:

- Regular Inspections and Maintenance: Conduct thorough inspections and perform routine maintenance on your choke manifold system to identify and address potential issues before they escalate.

- Staff Training: Ensure that personnel operating the choke manifold systems are well-versed in proper procedures and techniques, promoting worker safety and preventing operational errors.

- Documentation and Compliance: Maintain up-to-date records of inspections, maintenance, and any incidents involving the choke manifold system. Ensure that your choke manifold system complies with all regulatory standards and industry certifications.

Conclusion

Choke manifold systems play an indispensable role in maintaining safety and efficiency in the demanding oil and gas industry. These systems are critical for success in various drilling and production scenarios by effectively managing well pressure fluctuations and facilitating proper fluid control.

Partner with Tiger Safety Rentals for your choke manifold needs and benefit from our comprehensive range of high-quality equipment, technical expertise, and exceptional support. Don’t leave the safety and success of your oil and gas operations to chance.

Contact Tiger Safety Rentals today to discuss how our choke manifold solutions can safeguard and enhance the efficiency of your projects.